Xeuss Pro – Thế thế hệ thiết bị tán xạ tia X dạng beamline tối tân nhất trong phòng thí nghiệm

Tính linh hoạt tối đa

Hiệu suất cao nhất

Nhiều không gian cho môi trường mẫu

Xeuss Pro là thế hệ mới nhất trong dòng Xeuss đã được kiểm chứng và đã được lắp đặt tại các cơ sở nghiên cứu hàng đầu trên thế giới. Nó kết hợp tất cả những cải tiến mới nhất từ Xenocs để tăng thêm tính năng, tính linh hoạt và dễ sử dụng.

“It’s a piece of equipment that’s as easy to use as a coffee maker. And it’s a very low-risk way to visualize materials to see if it tells you something new.”

Professor Eric Cochran – Director of the Center for Bioplastics and Biocomposites (CB2), based at Iowa State University

Get big picture on your sample:

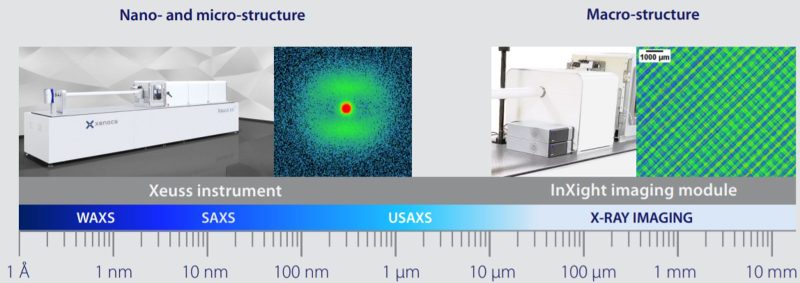

- Truy cập thông tin cấu trúc vật liệu từ Ångströms đến milimét với mô đun InXight

- Kích thước & phân bố kích thước hạt ( ISO 17876:2020)

- Nồng độ hạt (ISO/CD 23484)

- Diện tích bề mặt riêng của vật liệu xốp, kích thước và phân bố lỗ rỗng (ISO 20804)

- Hình thái học

- Cấu trúc bên trong (lõi/vỏ)

- Tương tác giữa các hạt

- Khối lượng phân tử

- Cấu trúc tinh thể (semi crystal, liquid crystal,…) hoặc vô định hình

- Độ xốp, trật tự và định hướng

- Mật độ điện tử, cấu trúc tinh thể và định hướng của màng mỏng

- ….

Ưu điểm:

- Có thể phân tích nhiều mẫu: rắn, lỏng, bột, nhão, gel, đục, sẫm màu,…

- Đa dạng vật liệu: vật chất mềm “soft matter”, hạt nano, sinh học (DNA, RNA, protein, liposome, lipid, enzyme, từ peptide đến virus); polyme, colloid, gel, màng mỏng, sợi,…

- Chuẩn bị mẫu đơn giản với lượng mẫu lớn mà không phá hủy mẫu

- Thiết kế SMART cung cấp khả năng phân tích trực tiếp từ mẫu tới kết quả

- Kết quả chính xác với dải đo động cao

- Kết quả mang ý nghĩa thống kê cao, giàu thông tin quan trọng bổ sung cho nhiều kỹ thuật khác như SEM, TEM, AFM, NMR, XRD, DLS, Raman,…

- Dễ dàng thực hiện thí nghiệm (In situ hay in operando) khi thay đổi nhiệt độ, áp suất, pH, độ ẩm, ứng suất,…

Đánh giá

Chưa có đánh giá nào.