Keep Your Process Up to Speed

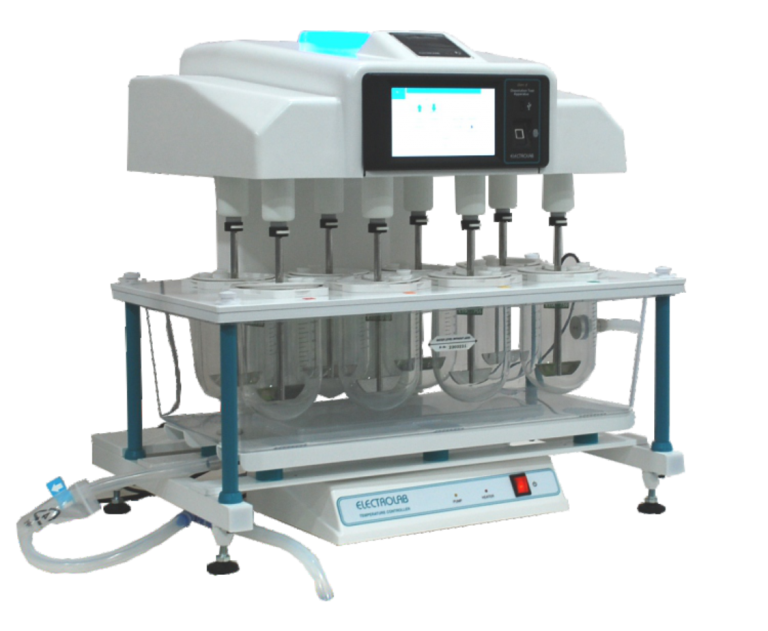

The Olympus Vanta™ iX in-line X-ray fluorescence (XRF) analyzer gives you confidence in your products by automating material analysis and alloy identification on the manufacturing line; delivers instant results for real-time process monitoring and 100% inspection; built to operate 24/7; configured to deliver pass/fail results, accurate grade ID, and material chemistry.

- High resolution: ID a range of alloy grades—including light and heavy elements

- Fast, accurate results: the analyzer provides speed, stability, and a high-count rate

- Efficient: features a silicon drift detector (SDD) and the proven Axon Technology™ found in every Vanta analyzer

100% Inspection for Metal Fabrication

For organizations adopting Industry 4.0 practices and 24/7 process control to verify alloys, the Vanta iX analyzer delivers material verification and lot/heat control for bar, billet, tube, and rod manufacturing, as well as machined parts and customized components. Automating your testing with a Vanta iX analyzer adds value to your finished product since you can demonstrate that materials are 100% tested and verified.

Scanning and Monitoring for Geo Processing

For geological processing and mining, the Vanta iX analyzer enables monitoring for core scanning and on-belt analysis with real-time results to monitor process variability and ensure ore grade consistency. During on-belt analysis, the analyzer provides blending verification and process validation of concentrates.

Intelligent Integration

The Vanta™ iX analyzer includes mounting holes that make it easy to attach to existing robotics and other systems. There is no external control box, so you can easily control the analyzer with either a PLC and discrete wire or through the Vanta Connect API.

Connector options:

- Ethernet (RJ-45), enabling Power over Ethernet

- USB

- Discrete I/O (16 pins)

- AUX DC power

Rugged for the Manufacturing Line

The Vanta iX analyzer is built to endure the high levels of vibration, electromagnetic and acoustical noise, dust, and moisture of production facilities.

- Vibration and mechanical shock tested (MIL-STD-810G)

- IP54 rated

- Designed to operate from –10 °C to 50 °C (14 °F to 122 °F) with continuous testing

A built-in heat sink lowers the internal temperature, while fan attachment points are available for additional cooling. The analyzer offers toolless window changes for fast maintenance.

Application

- Foundry feed grade control

- Alloy ID grade control (metal works)

- GeoChem feed and Grade control

- Coating thickness (electronics and galvanised steel manufacturing)

Video

Reviews

There are no reviews yet.