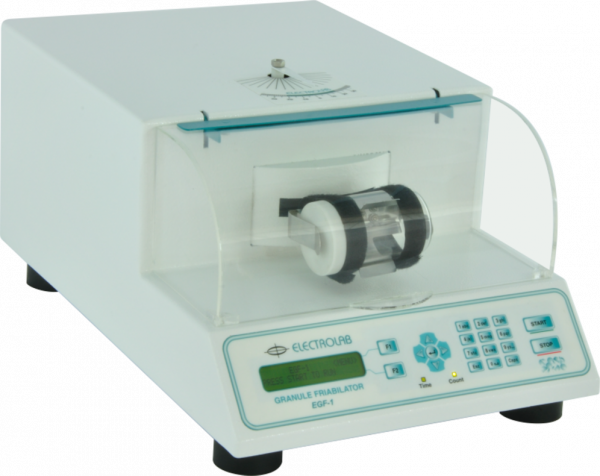

EGF-1 granule friability tester

Model: EGF-1

Brand: Electrolab

Origin: India (Ấn Độ)

EGF-1 granule friability tester: The specialized solution for granules and pellets

Unlike tablets, the mechanical strength of granules and pellets requires a specialized testing method. The EGF-1 granule friability tester is specifically designed to meet this need, strictly complying with the specifications of the European Pharmacopoeia (Ph. Eur.) and providing a precise, quantifiable method for determining the friability of these dosage forms.

With its unique bi-directional horizontal shaking mechanism, the EGF-1 is an indispensable tool for the research, development, and quality control of granule-based products.

Specialized features of the EGF-1 granule friability tester

This instrument is built with unique features focused on accurately simulating the physical stresses on granules and pellets.

Compliance with European Pharmacopoeia (Ph. Eur.): The entire design and operating principle of the instrument comply with Ph. Eur. chapter 2.9.41, ensuring that test results are valid and recognized.

Bi-directional horizontal shaking mechanism: Instead of the tumbling motion used in tablet friability testers, the EGF-1 employs a horizontal shaking mechanism at a 37° angle, creating a gentle sliding and impact action suitable for the nature of granules.

Precise control of the test process: Allows users to program the shaking rate (from 0 to 400 oscillations/minute) and test duration (from 1 to 9999 seconds), making it easy to standardize and replicate methods.

Safe and observable design: A clear acrylic lid allows for sample observation throughout the test and features a magnetic interlock to ensure the machine only operates when the lid is safely closed.

Increased throughput: Uses interchangeable 105 ml glass sample containers, which facilitates rapid preparation and switching between samples.

Detailed specifications

| Attribute | Specification |

| Model | EGF-1 |

| Shaking angle | 37° |

| Shaking rate | Programmable from 0 to 400 oscillations / min |

| Time | 1 to 9999 sec |

| Dimension (W x L x H) | 468 x 304 x 237 mm |

Material options and ordering information

The EGF-1 offers options for the body material to suit the needs and budget of different laboratories:

Stainless Steel (S.S.): The premium choice, offering corrosion resistance and ease of cleaning, suitable for environments requiring cGMP standards.

Mild Steel (M.S.): A more economical option that still ensures durability and operational performance.

Frequently asked questions (FAQ)

H3: What is the difference between this and a tablet friability tester?

The biggest difference lies in the mechanism. A tablet friability tester uses a rotating drum to create a tumbling and free-fall motion. In contrast, the EGF-1 granule friability tester uses a bi-directional horizontal shaking mechanism, which creates a sliding and frictional action more appropriate for assessing the durability of small granules.

H3: Why is compliance with the European Pharmacopoeia (Ph. Eur.) important?

The European Pharmacopoeia (Ph. Eur.) is one of the world’s leading references for pharmaceutical quality standards. The fact that this instrument complies with Ph. Eur. chapter 2.9.41 ensures that your testing method and results are consistent, comparable, and widely accepted globally.

H3: What is the purpose of the 37° shaking angle?

The 37° shaking angle is a specification defined in the European Pharmacopoeia. This angle is designed to ensure that the granules slide and collide optimally within the container, accurately simulating the mechanical stresses they might encounter in reality.

H3: What is the difference between the stainless steel (S.S.) and mild steel (M.S.) body options?

A stainless steel (S.S.) body offers superior resistance to rust and corrosion, is easy to clean, and is suitable for laboratories with high standards for cleanliness and cGMP. A mild steel (M.S.) body is a more cost-effective solution that still provides excellent mechanical durability for the instrument.

Be the first to review “EGF-1 granule friability tester” Cancel reply

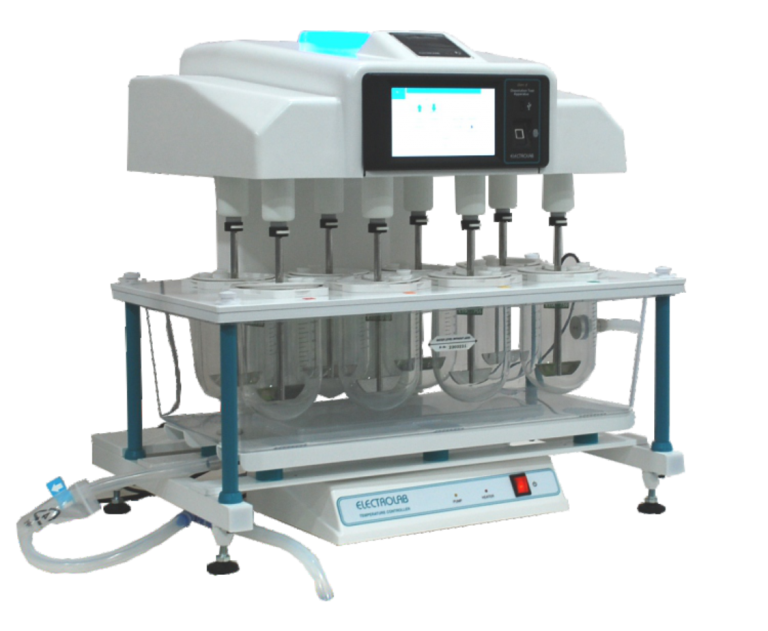

Sản phẩm liên quan

Reviews

There are no reviews yet.