NEW TECHNOLOGY & PRODUCTS, News

5 Advantages of Olympus XRD Analyzers over Conventional XRD Instruments

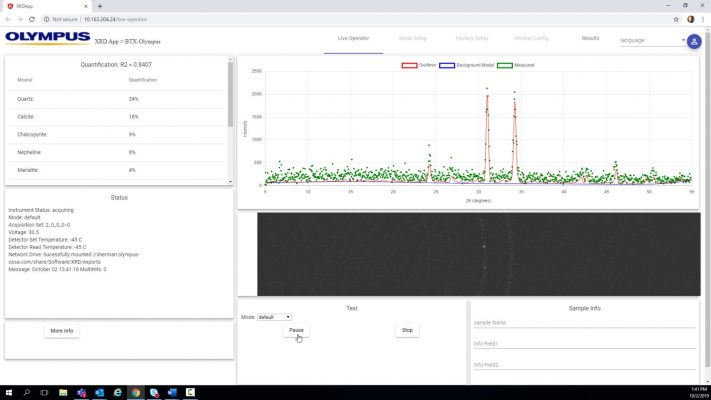

X-ray diffraction (XRD) is a technology used to identify and quantify minerals that have a crystalline structure. Olympus XRD analyzers have some important differences from conventional XRD instruments that result in greater portability and faster results. Check out 5 features that make our XRD instruments innovative and uniquely viable for in-the-field X-ray diffraction analysis.

1. Better Signal-to-Noise Pattern

Our detectors are position and energy sensitive, meaning that they automatically subtract noise that is not being used by the XRD experiment. This contributes to automatic noise reduction. The SmartSense filter selectively removes the X-ray counts caused by fluorescence to provide a better signal-to-noise pattern.

2. Lower Power Consumption and Operator Cost

Because the instrument’s X-ray tube and detector are very close to the sample, the power of the analyzer’s X-ray tube can be reduced without sacrificing the number of available photons compared to the long optical pathways of large, conventional XRD instruments. Lowering the power of our instruments’ X-ray tubes minimizes the need for and the expense and maintenance associated with external cooling and results in overall lower power consumption.

3. Small, Portable Instruments that Yield High-Quality Data

Conventional XRD instruments use a goniometer, a large device that rotates the X-ray tube and detector around a stationary sample. Goniometers are cumbersome and need to be calibrated. Olympus XRD analyzers use a charge coupled device (CCD) area detector that captures the entire practical scanning range simultaneously, eliminating the need for a goniometer.

Our XRD analyzers work by encapsulating 15 mg of powdered sample between two film windows. Next, the device applies a constant frequency using a piezoelectric generator, and this frequency has the effect of convecting the powder in what’s known as powder liquefaction. The technique convects the sample from bottom to top and rotates each particle on its axes, providing 100% randomization, something essential for producing high-quality mineralogy data. Because our analyzers use a transmitted X-ray analysis, the results don’t suffer from the same dense matrix induced peak broadening effects that many conventional XRD systems do.

The result of these novel technologies is small benchtop systems, like the BTX II™ analyzer and the portable TERRA® XRD analyzer that can be used right in the field.

4. Easy Sample Preparation

Our XRD instruments only need about 15 mg of sample per analysis. In comparison, some conventional XRD systems require a full 1 to 2 grams of sample. In addition, many conventional XRD analyzers require users to grind their sample to an ultra-fine powder of less than 20 µ. Because of our convective transmission technology, specimen particle size is less critical than with traditional goniometer-based systems; our optimum particle size is between 90 and 120 µ, something easily achieved with a mortar and pestle.

5. Fast Analysis

Conventional 2 kW instruments take a few seconds to collect each 2-theta measurement, and scanning entire 2-theta range can take as long as several hours. The CCD detector used in our instruments collects the entire 2-theta range simultaneously, so the complete diffraction pattern is visible almost immediately.

Learn more about the family of Olympus X-ray diffraction instruments.

Related Content

- Video: Quantitative Mineralogy with Olympus XRD

- Out of this World: Olympus XRD on Mars

- Case Study: X-ray Diffraction for Mineral Processing