NEW TECHNOLOGY & PRODUCTS, News, Science and Life

CBE’s new Small Angle X-Ray Scattering unit will benefit many ISU researchers

“It’s a piece of equipment that’s as easy to use as a coffee maker. And it’s a very low-risk way to visualize materials to see if it tells you something new.”

The simplicity, yet high value of, the Department of Chemical and Biological Engineering’s Small Angle X-Ray Scattering System (SAXS) is summed up in that one statement from Professor Eric Cochran, who oversees the department’s impressive new addition to its lab equipment roster.

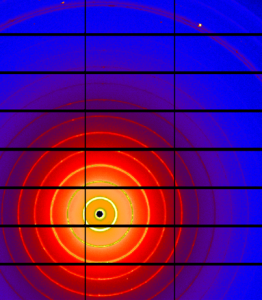

SAXS offers researchers a major step up in their ability to gain highly detailed information about those materials – all kinds of materials. Not just the size and shape of particles that make up something, but information about the internal structure of systems – in some ways surpassing what can be done with an electron microscope.

“It’s used as a complement to what you do with the electron microscope,” Cochran says. “With electron microscopy you use an electron beam to have a look at an extremely small volume of material. You get a picture of what it looks like – and it looks just like an object magnified many times. Everyone can relate to that. X-ray scattering with SAXS gives you the same information, but the benefit is, that information is averaged over a much larger volume.” And then there is the all-important “no cheating” factor. “In regular microscopy you can ‘cherry pick’ images you get to make things look good. With SAXS, whether intentional or not, you don’t get to cherry-pick things,” he explains. “It is a true no-nonsense visualization. You can use the technology to study proteins, RNA, DNA, quantum dots, quantum rods, polymer melts, polymer solutions and many other things that scientists constantly use for research.”

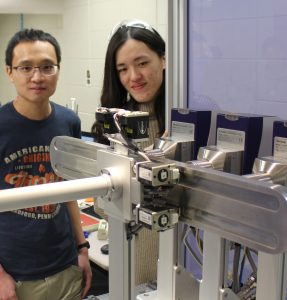

What’s unique about SAXS is the great range of control an operator has over the size of the features of something he or she wants to analyze. “With a microscope, you have different lenses you use for different things. In SAXS, we use the length of the instrument itself to control the size of things visualized, from minute to mesoscale,” says Cochran. And, a highly valuable component of SAXS measurements show the changes that materials undergo while they are exposed to different active forces such as heating, cooling, shearing and stretching. Cochran’s goal is to have many departments on campus use the device – and an early test involved analyzing a sample of vibrationally-welded wood from another department. It’s a newer technique that can rapidly produce wood joints for structural applications. “We used SAXS and looked at how things held up or changed across the weld that was employed between the two pieces of wood,” he says.

Planning was long and detailed prior to the arrival of this new level of technology in the department. Two existing rooms in the Sweeney Hall basement were completely remodeled to accommodate the SAXS. They say good things come in small packages, but there was nothing small about the shipping of the unit’s components from its country of origin, France. Fourteen crates ranging in size from that of a coffee table all the way up to “we’re gonna need some extra guys on this one” arrived at Sweeney in the fall of 2017, six months after he original order had been drawn up.

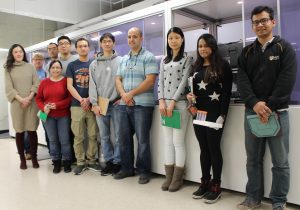

The planning and purchasing of the unit was a cooperative venture, as will be the use of it going forward. Iowa State’s College of Agriculture and Life Sciences and College of Liberal Arts and Sciences joined the College of Engineering (totaling 12 different departments and 23 principal investigators) in a cost-sharing agreement for purchasing of the unit. “In this way we were able to justify the cost of purchasing many different accessories for the unit,” says Cochran, pointing out the versatility of the SAXS in being able to be easily set up for many different kinds of functioning. “Set up with the accessories, it really is a big Swiss army knife, a Jack-of-all-trades instrument.” The total cost of the unit was approximately $1 million.

Of course, graduate students in Cochran’s research group and other ISU chemical engineering grad students will consistently benefit from the unit. User rates will be set up for other departments, and an agreement exists for a mail-in service for analyses and results with the University of Iowa chemical engineering and chemistry departments. Cochran says he would like to work toward hiring a full-time scientist to manage the SAXS unit to schedule use and oversee experiments done: “I want to see that unit in use 24 hours a day.”

Source: Iowa State University, College of Engineering News