Nanomaterials play an increasing role in industry and everyday life. They provide surfaces with special abilities, improve product durability and colour or have outstanding physical properties. However, many measurement methods cannot accurately characterize such nanomaterials due to their very small size. In 2018, BAM researchers started working with one of the world’s best nanostructure measurement instruments. This new equipment is designed to help enable the safe and sustainable use of innovative nanomaterials throughout their lifecycle, including production, recycling or disposal.

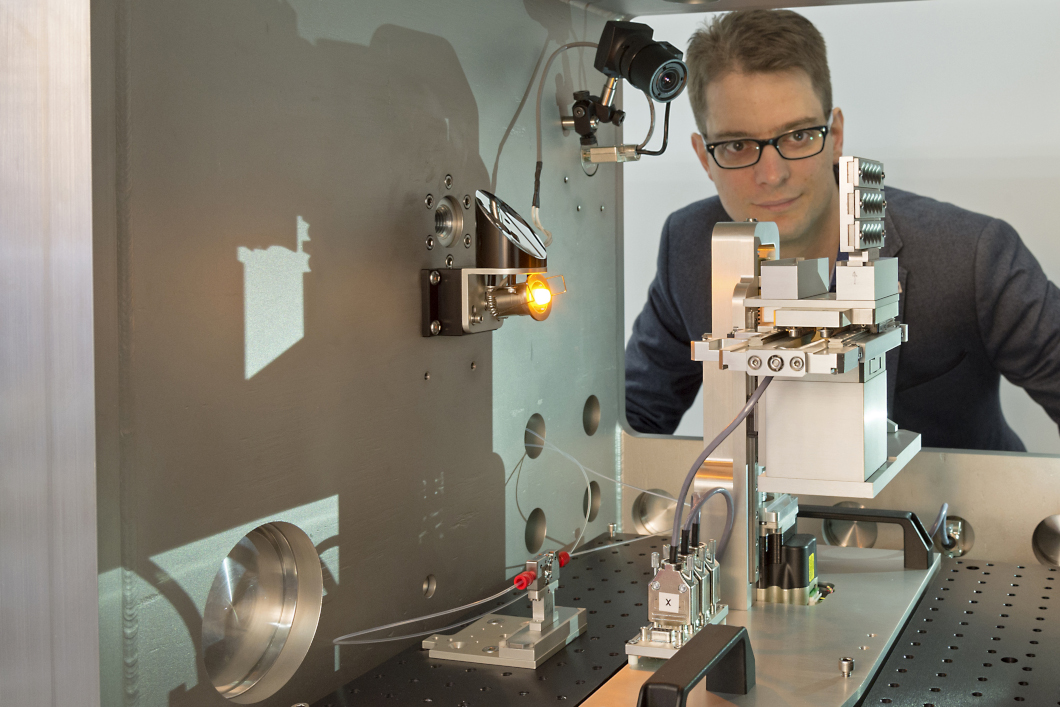

In November 2017 a dream came true for Dr. Brian Richard Pauw. “I have always wanted to combine the best parts of all the instruments in my field into a single device” says the scientist from the Polymers in Life Sciences and Nanotechnology division. Dr. Pauw is an expert in structure elucidation for tiny nanoparticles and nanostructured materials using small-angle X-ray scattering (SAXS). He has continually gathered new ideas for an optimal SAXS instrument during his work in the Netherlands, Denmark and Japan. With the “Multi-scale Analyzer for Ultrafine Structures”, or “MAUS” for short, most likely the world’s best laboratory instrument for measuring small-angle X-ray scattering is now available at BAM.

Due to the importance of nanomaterials, BAM has been working hard on developing innovative measuring methods to characterize them. While most SAXS devices can only measure a mean particle diameter between a few nanometers and about 300 nanometers, this new device can provide a far more comprehensive look. The roughly six-meter-long MAUS can analyze structures within a range of 0.2 to 2000 nanometers in large sample volumes. “We want to continue to optimize the instrument and we are researching hard to expand the range of materials that these SAXS measurements can be applied to,” says Pauw.

An instrument with unique features

“Technically speaking, MAUS is quite unique and combines many good features,” explains Pauw. The device has two X-ray radiation sources which can examine samples with different X-ray energies. Large amounts of sample can be irradiated at different angles while the extremely movable detector on a three-axis table allows the measuring device to be adapted to many different measurement configurations. In addition, this instrument enables regular, multi-day measurements. “This allows us to investigate changes in nanostructures over time and easily track slow processes such as ageing,” explains Pauw.

Ready for use for different materials

SAXS is an important measurement technology for looking into the nanoworld. It provides an average measurement of the size of nanoparticles and nanostructures present in a sample. The device is suitable for all common materials that have a nanostructure, and SAXS measurements can be used for materials in industry or research, ranging from metals to polymers, oils, plastics and even proteins. Almost all conventional measuring methods fail in statistically relevant dimensional characterization of nanoparticles because they are not sensitive enough to their small size. “Small-angle X-ray diffraction can do what electron microscopy never could,” says Pauw, explaining the versatility of SAXS. “It can characterize the nanostructures of large amounts of material with a minimum of effort,” he adds. This is of interest for both scientists and quality assurance. Pauw, for example, has studied the nanopores in aramid fibres used in the construction of gliders and bullet-proof vests.

Stumbling block: Processing the data

“For the last 100 years, one of the biggest stumbling blocks for small-angle X-ray scattering has been the analysis of the collected data,” explains Pauw. His ongoing work is to develop measurement and analysis methods that can reliably extract relevant structural information from the data. That MAUS can measure such small objects accurately is mainly due to the data correction methods developed by Dr. Pauw. Without these, researchers run the risk of unwittingly interpreting the measurements’ artefacts as real measurement results.

The MAUS is also available to partner institutes and universities to accelerate the use of small-angle X-ray scattering as a standard method in science and industry through professional exchange. Already in 2018, more than 10 external users were hosted, the results of which are being included in several upcoming publications. “We very much welcome collaborations with both academia as well as industry, and recommend interested parties to stop by for an informal discussion on the possibilities,” says Dr. Pauw.

As a result of this work by BAM, SAXS can be included as one of the main methods of investigating these small structures in new EU regulations for nanomaterials. “Examining products with nanoparticles not only serves the safety of consumers, but also improves materials in many ways,” explains Pauw. The Berlin team has already used MAUS to investigate improved aluminium alloys, new catalysts for the chemical industry and porous materials for membranes.

Source: BAM