Source: BAM

Whether in cosmetics, textiles, electronics or food, nanoparticles exist in many everyday products where they influence colour, effectiveness or durability. The Bundesanstalt für Materialforschung und -prüfung (BAM) performs research into the effects of nanoparticles on health and the environment. In addition to other methods, small-angle X-ray scattering (SAXS) is used to measure the amount and size of nanoparticles in samples. Here, BAM has set a milestone by commissioning a unique laboratory SAXS device.

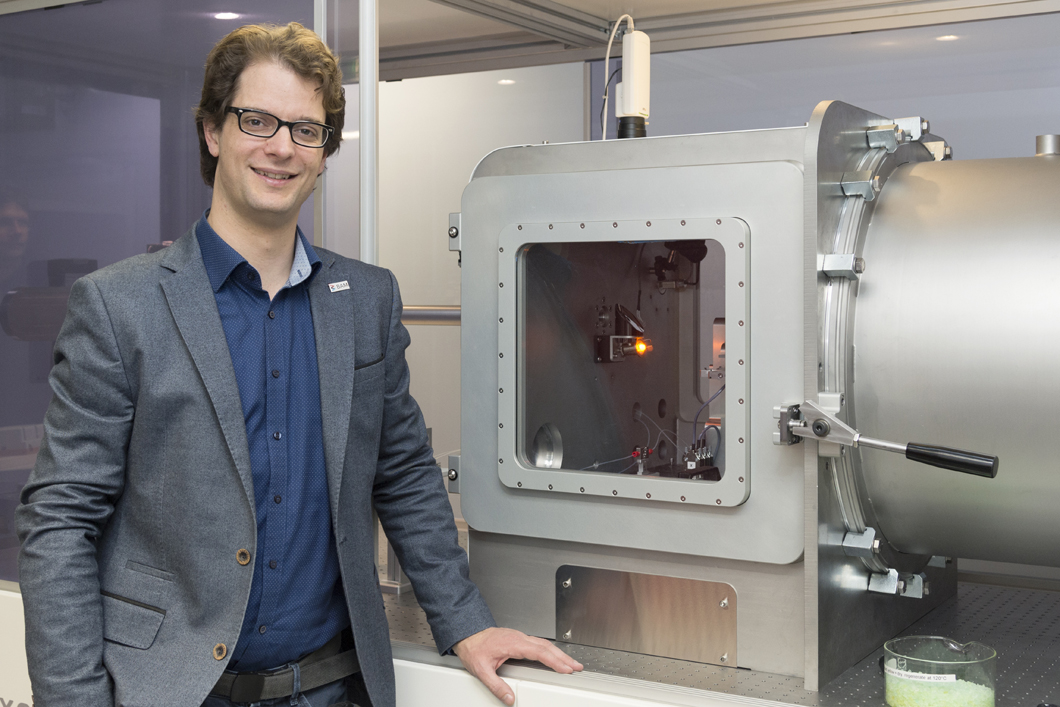

The six-meter-long “Multi-scale analyzer for ultrafine structures”, or MAUS for short, can quantify nanostructures over an unprecedented wide range from 0.2 to 2000 nanometers in large sample volumes. New data correction and evaluation methods developed at BAM complete the instrument, and are essential to reaching its full potential. As a further deviation from the standard laboratory instruments, the MAUS will also be accessible to partner institutes and universities, to accelerate the exchange of ideas and speed up the further development and standardization of SAXS.

From SAXS to MAUS: nano silver particles go around the world

“The investment was preceded by a worldwide study, to find out how similar the results from the vastly different SAXS instrument designs are. In this way, we find out if SAXS is a reliable measuring method in nanoanalytics”, explains BAM scientist Dr. Brian Pauw, who has been researching SAXS for a long time, leading the design and construction of the device. To study this, BAM sent uniform samples with silver particles to 22 leading laboratories. The findings were surprisingly good, exhibiting a 90 – 98% accuracy. “These results show that SAXS – if done correctly – is a reliable nanoparticle and nanostructure measuring method.”

Prof. Heinz Sturm heads the Materials Protection and Surface Technology Division and the Nanotechnology Working Group and adds: “In order to meet future demands, the process must be continually refined and expanded in accordance with current requirements. We therefore see the investment in the new laboratory SAXS device MAUS as key, also with regard to international cooperation.”

BAM is researching into a safe and compatible use of nanomaterials

Our research is aimed at the safe and compatible use of innovative nanomaterials throughout their entire life cycle: from material development through production, processing, and use to recycling or disposal. BAM President Prof. Ulrich Panne emphasizes: “Whether it is about improving flame retardance of plastics or making the bodies of cars and airplanes safer, our basic research and development and definition of European and international standards make an important contribution to the safety of nanotechnology.”

About BAM

BAM promotes safety in technology and chemistry.

As a BMWi departmental research institute, BAM performs research, testing and offers advisory support to protect people, the environment and material goods. Its activity in the fields of materials science, materials engineering and chemistry is focused on the technical safety of products and processes.

BAM’s research is directed towards substances, materials, building elements, components and facilities as well as natural and technical systems important for the national economy and relevant to society. It also tests and assesses their safe handling and operation. BAM develops and validates analysis procedures and assessment methods, models and necessary standards and provides science-based services for the German industry in a European and international framework.

Safety creates markets.

BAM sets and represents high standards for safety in technology and chemistry for Germany and its global markets to further develop the successful German quality culture “Made in Germany“.

Source: BAM